7 Easy Facts About Wedge Barriers Described

Table of ContentsThe Buzz on Wedge BarriersThe Buzz on Wedge Barriers

18 might be done more rapidly, conveniently, and expense properly. FIG. In certain embodiments, the anchor 30 might be a steel structure consisting of plates, beams(e. g., I-beams ), and/or various other structures that are secured within the foundation 14, which may be concrete. At the surface area 12, an upper side 28 of the anchor 30 might be at the very least partially exposed

, thus allowing the attachment of the barrier 10 to the support 30. g., threaded holes)in several beams or plates of the support 30 might be revealed to the surface area 12. In this manner, screws 32 or other mechanical bolts might be utilized to protect the obstacle 10 to the support 30. As the barrier 10 is mounted to the surface area 12 of the foundation 14, collection of debris and various other material underneath the obstacle may be reduced, and parts of the bather 10 might not be subjected to below grade atmospheres. As indicated by reference numeral 52, the training mechanism 50 consists of parts got rid of underneath the wedge plate 16. The parts 52 underneath the wedge plate 16 may include an electromechanical actuator, a webcam, one or even more cam surface areas, and so forth. Furthermore, the training mechanism 50 includes a spring setting up 54

The springtime pole 58 is coupled to a web cam(e. g., cam 80 displayed in FIG. 4) of the lifting mechanism 50. The springs 60 disposed concerning the springtime pole 58 are held in compression by springtime supports 62, including a fixed spring support 64. i was reading this That is, the set springtime support 64 is fixed relative to the structure 14 et cetera of the bather 10.

10 Easy Facts About Wedge Barriers Described

The continuing to be force used to

the cam webcam deploy the wedge plate 16 may be provided by an electromechanical actuator 84 or other various other. The spring assembly 54 and the actuator 84(e. Wedge Barriers. g., electromechanical actuator)might run with each other to translate the web cam and lift the wedge plate 16.

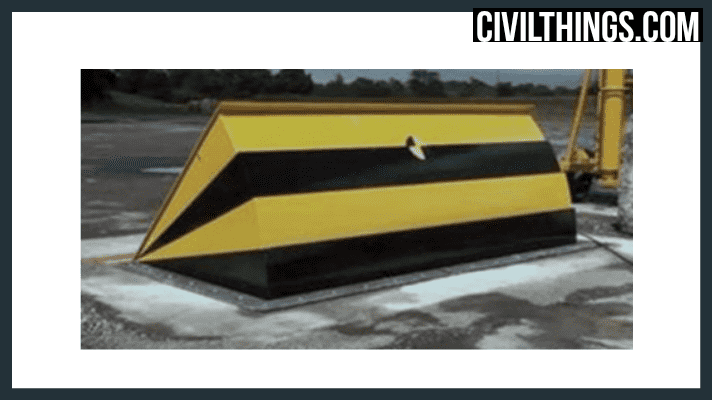

As discussed over, the spring assembly 54 exerts a continuous pressure on the webcam, while the electromechanical actuator may be regulated to exert a variable force on the cam, consequently making it possible for the lifting and reducing( i. e., deploying and retracting )of the wedge plate 16. In particular personifications, the continuous force used by the spring assembly 54 might be flexible. g., electromechanical actuator) is disabled. As will certainly be appreciated, the springtime assembly 54 may be covered and secured from particles or other elements by a cover plate(e. g., cover plate 68 displayed in FIG. 4) that may be significantly flush with the raised surface 38 of the structure 14. As stated above, in the released position, the wedge plate 16 offers to obstruct gain access to or travel past the obstacle 10. The barrier 10(e. g., the wedge plate 16 )may obstruct pedestrians or automobiles from accessing a building or path. As discussed over, the obstacle 10 is affixed to the anchor 30 safeguarded within the structure 14,

front braces 71. As a result, the link settings up 72 might pivot and rotate to make it possible for the collapse and extension of the affiliation assemblies 72 throughout retraction and release of the bather 10. The linkage assemblies 72 cause movement of the wedge plate 16 to be limited. If a car is traveling towards the deployed wedge plate 16(e. For instance, in one circumstance, the security legs 86 may be expanded duringmaintenance of the barrier 10. When the security legs 86 are deployed, the safety and security legs 86 support the weight of the wedge plate 16 against the surface area 12. Therefore, the lifting device 50 might be deactivated, serviced, removed, replaced, etc. FIG. 5 is partial perspective sight of a personification of the surface-mounted wedge-style barrier 10, highlighting the web cam 80 and the cam surfaces 82 of the training mechanism 50. Particularly, 2 web cam surfaces 82, which are referred to as reduced cam surface areas 83, are positioned below the cam 80. The lower cam surfaces 83 may be their website taken care of to the surface 12 (e. As an example, the lower cam surfaces 83 and the placing plate 85 might form a single piece that is safeguarded to the support 30 by screws or other mechanical fasteners. Furthermore, two web cam surface areas 82, which are referred to as upper webcam surface areas 87, are placed above the web cam 80 and combined to (e. In other personifications, stepping in layers or plates might be positioned between the surface 12 and the lower webcam surfaces 83 and/or the wedge plate 16 and the upper web cam surfaces 87 As mentioned above, the web cam

80 translates along the cam surface areas 82 when the wedge plate 16 is lifted from the retracted setting to the released placement. In addition, as mentioned above, the spring assembly 54 (see FIG. 3 )may offer a force acting on the camera 80 in the instructions 102 by means of springtime pole 58, which may decrease the force the electromechanical actuator 84 is required to put on the cam 80 in order to actuate and raise the wedge plate 16. 1 )to the deployed placement(see FIG. 4). As revealed, the web cam 80 includes track wheels 104(e. g., rollers), which call and convert along the webcam surfaces 82 during procedure.